DESCRIPTION

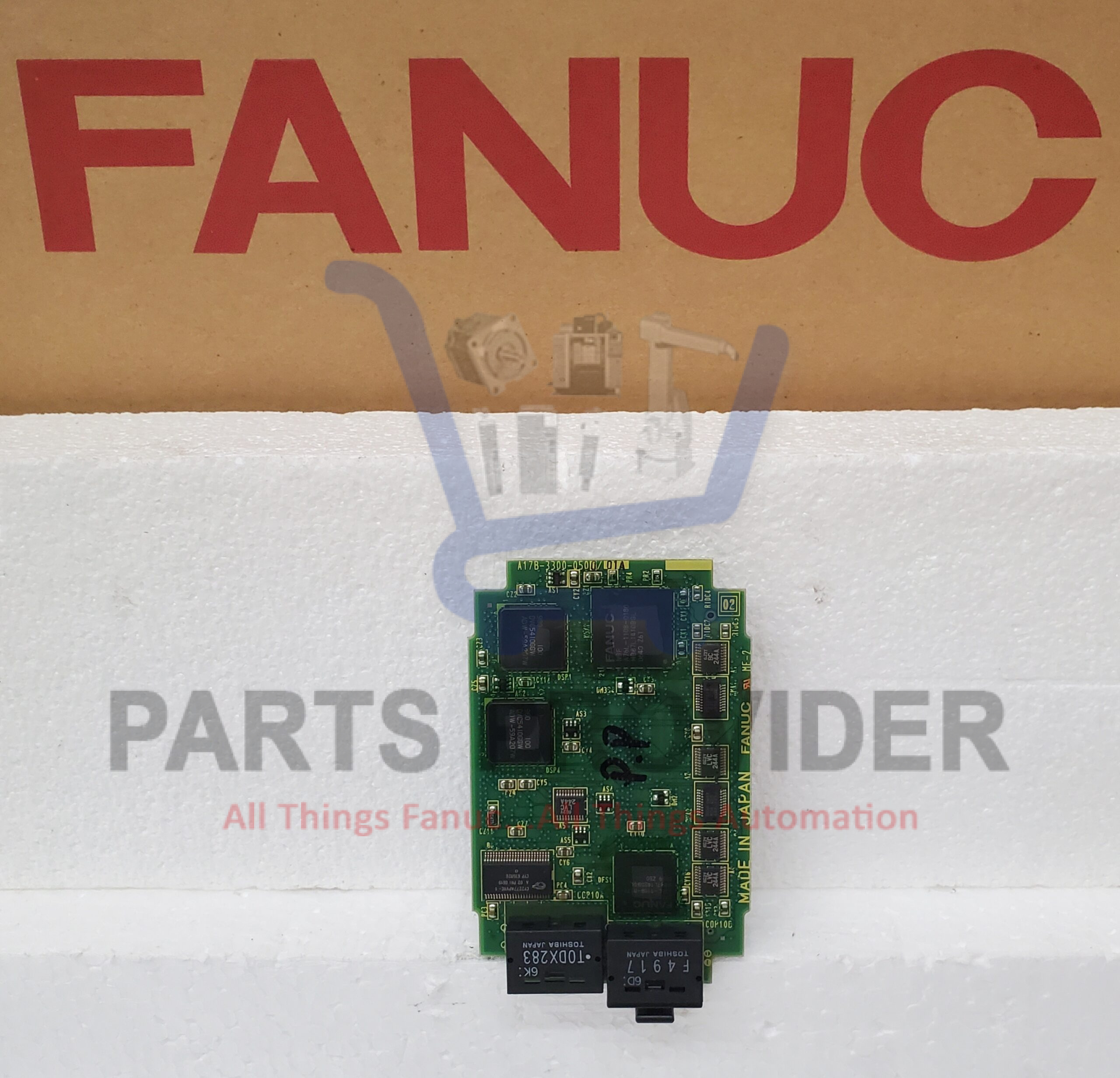

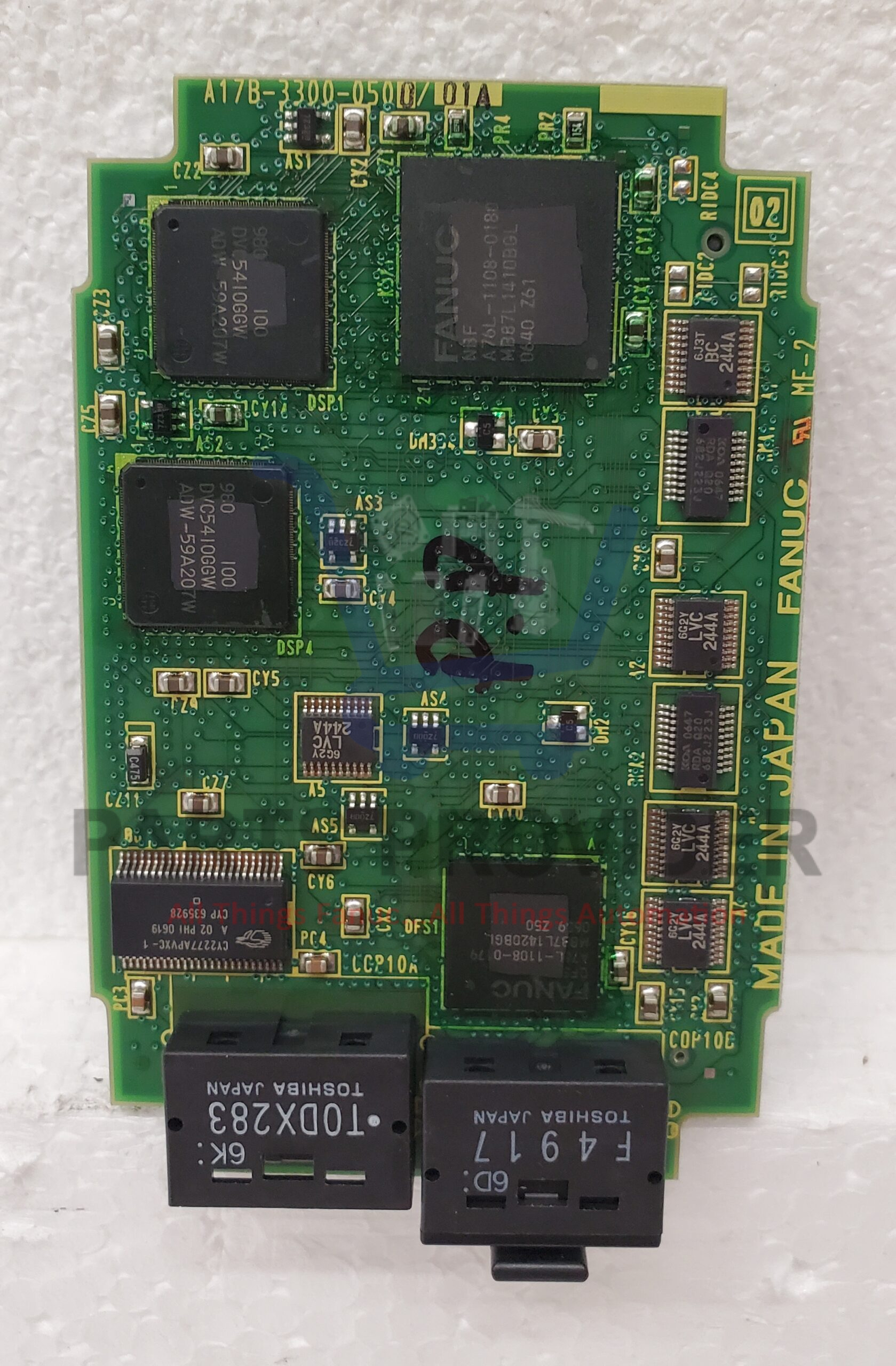

Part number: A17B-3300-0500

Description: FSiB 8 AXES SERVO MODULE HRV (REPLACES A20B-3300-0244)

Product Series: A17B-3300

FANUC HRV Overview

FANUC HRV, or High Response Vector Control, is an advanced technology used in CNC machining and robotics. It’s designed to enhance performance and improve the efficiency of machinery by using cutting-edge algorithms and high-speed processing techniques.

Key Features of FANUC HRV

- High-Speed Processing: Uses digital signal processors (DSPs) for real-time control, ensuring rapid response to changes in operational conditions.

- Nano-Interpolation: This technique allows for finer adjustments in movements, resulting in superior surface finishes and reduced cycle times.

- Enhanced Accuracy: Employs high-resolution encoders (up to 32,000,000 counts) which contribute to precise positioning.

- Dynamic Resonance Filtering: Auto-following filters actively minimize mechanical resonance, improving operational stability even during frequency variations.

Benefits of HRV Technology

- Improved Surface Finish: Creates finer and smoother finishes on machined parts.

- Reduced Cycle Times: Optimizes machining operations, enhancing overall productivity.

- Higher Accuracy: Ensures precise control of movements and positioning.

- Mechanical Resonance Control: Improves reliability and stability during operations.

FANUC HRV technology is particularly beneficial for manufacturers looking to improve their production capabilities by adopting state-of-the-art CNC systems. Continuous innovations ensure that companies leveraging this technology can stay competitive in the fast-evolving manufacturing landscape.

HRV technology is suitable for a variety of machining applications, including:

- 5-Axis Machining: Ideal for complex geometries requiring high precision.

- High-Volume Production: Efficient for repetitive tasks in manufacturing settings.

- Advanced Machining: Supports intricate designs that demand superior control